What is PHOSCOR® ?

PHOSCOR® G is a non-toxic, modified calcium phosphate-based anti-corrosive pigment that can successfully replace zinc phosphate, which is widely used in the coating industry. These are inorganic compounds that are chemically stable, providing proven long-term protection against corrosion. PHOSCOR® pigments are suitable for most types of paints and coatings, making them a universal anti-corrosion pigments. Their formula has been refined over the years to ensure optimal efficency and durability. PHOSCOR® is an effective solution for various industrial and commercial applications, providing long-lasting protection for metal surfaces.

Sustainable development

We are committed to sustainability, aiming to minimize our environmental impact. We strive for energy independence by embracing renewable sources and actively seek pro-eco solutions to contribute to a greener, more sustainable future.

WELCOME

About Ecor

Ecor is a producer of anticorrosive pigments, based in Poland. Established in 1982, our company has evolved through generations. Over the years, through continuous improvement, we have elevated our processes and products to meet the highest standards in quality and performance. Today, Ecor continues to work in the field of corrosion protection, offering sustainable solutions trusted by industries worldwide.

ANTICORROSION PIGMENTS

PHOSCOR® G

Modyfied Calcium Orthophosphate without zinc

ENVIROMENTAL SAFENESS

Prioritize environmental safety with nontoxic PHOSCOR® G, safeguarding human health and the environment, a choice for sustainable and eco-friendly solutions.

COST EFFECTIVE

The PHOSCOR® corrosion inhibitors are a highly competitive alternative in terms of both price and quality to the current anticorrosive pigments on the market.

ZINC PIGMENTS SUBSTITUTE

Our pigment can be used interchangeably with zinc pigments, as they are equally effective. The advantage of PHOSCOR® G pigment is it's non-toxicity.

MULTIPLE APPLICATION

Ecor anticorrosion pigments find diverse applications, providing robust protection across various coating bases - water and solvent.

LONG LASTING PROTECTION

Increase durability with inorganic PHOSCOR® pigments and minimize blistering and rust creepage. PHOSCOR® exhibits greater stability than organic inhibitors, being resistant to prolonged atmospheric conditions.

RELIABLE PARTNER

Due to our reliability, numerous clients have placed their trust in us, resulting in enduring, fruitful partnerships that have lasted for years.

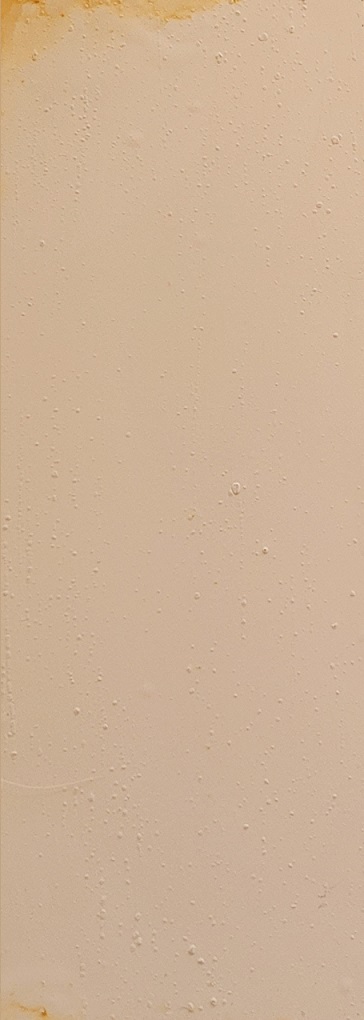

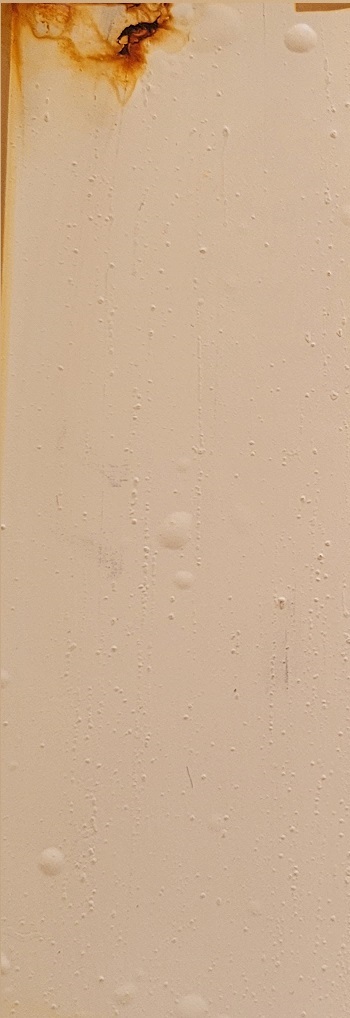

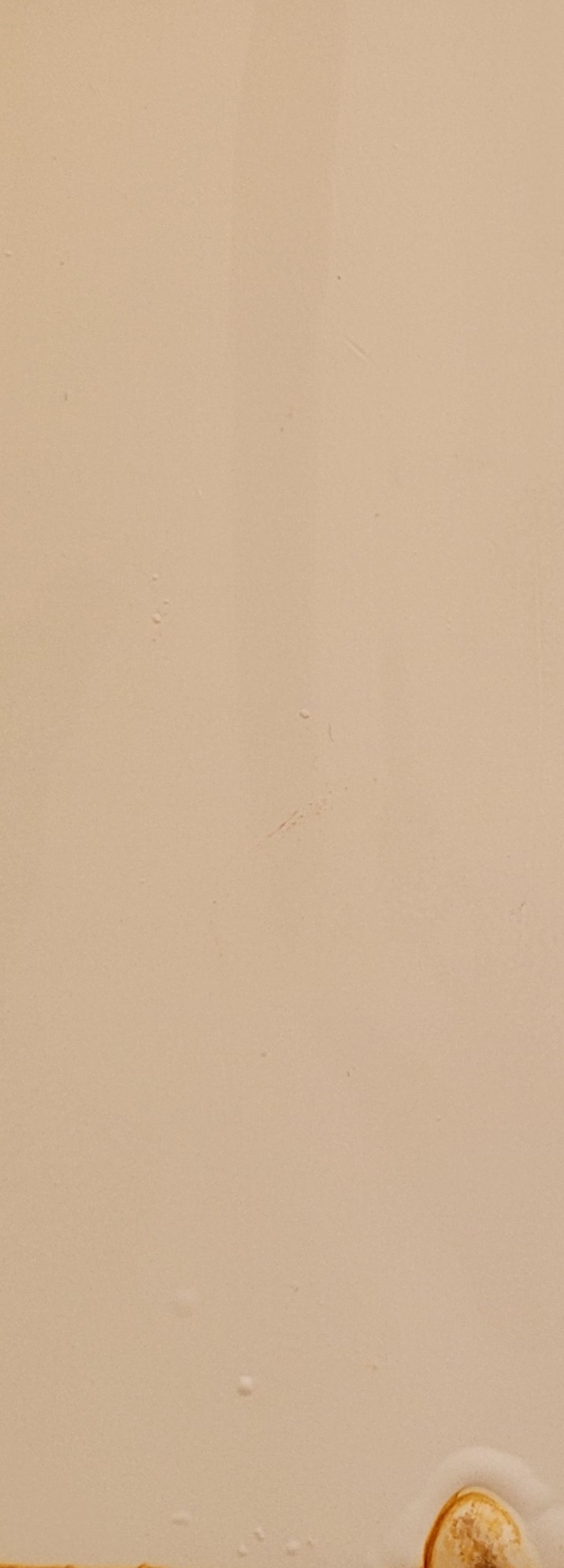

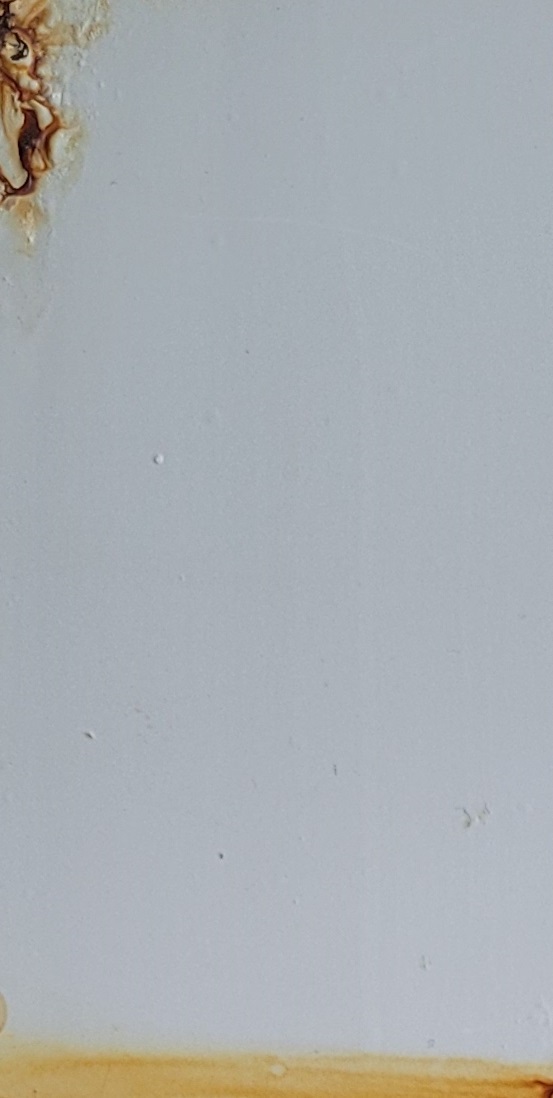

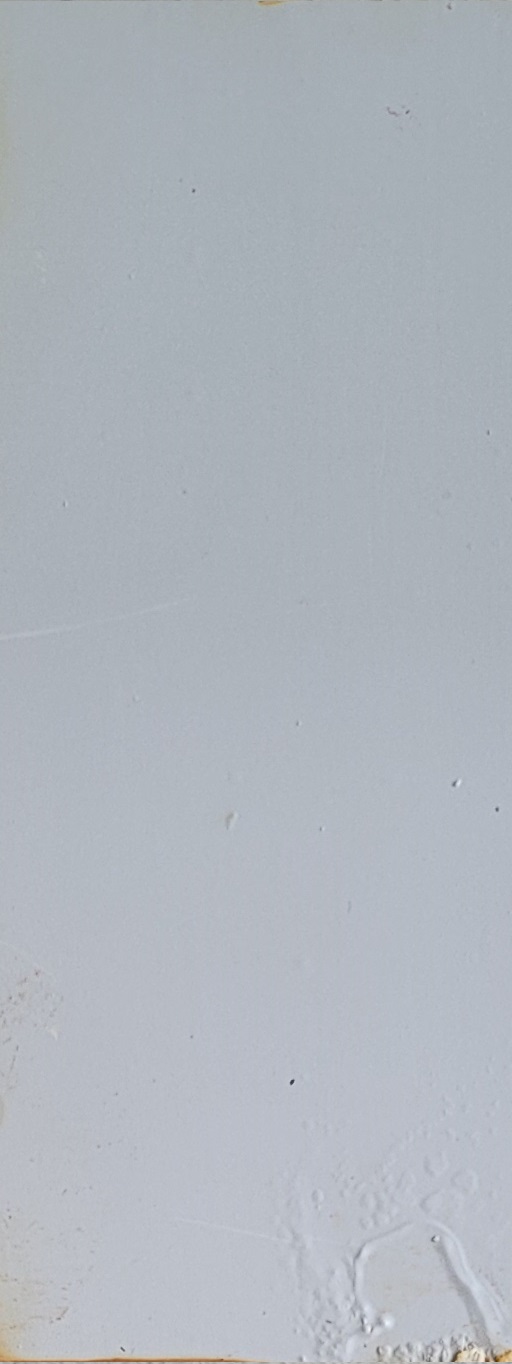

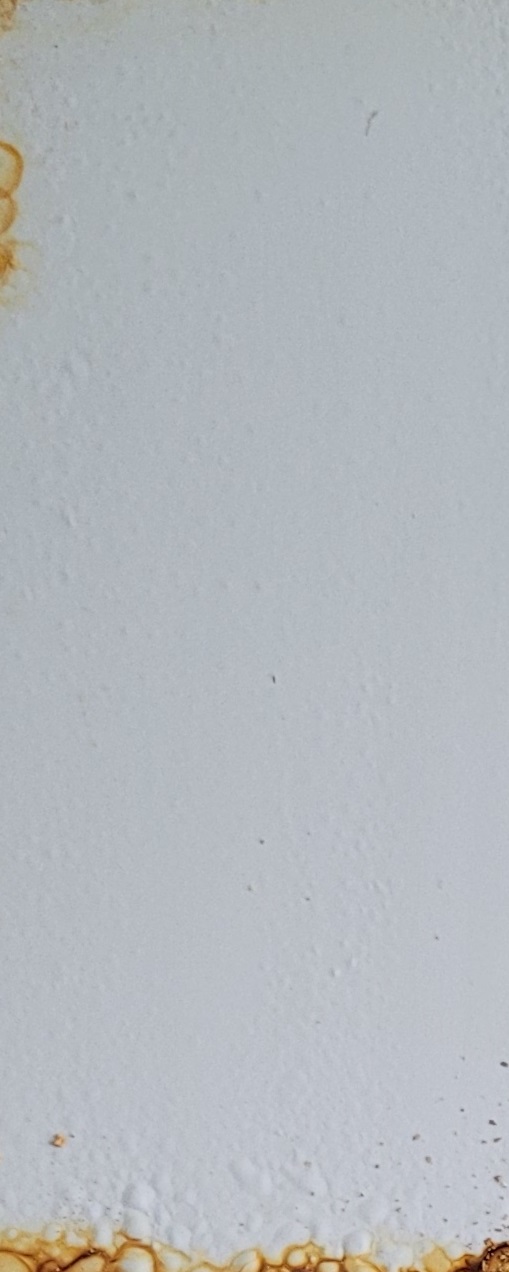

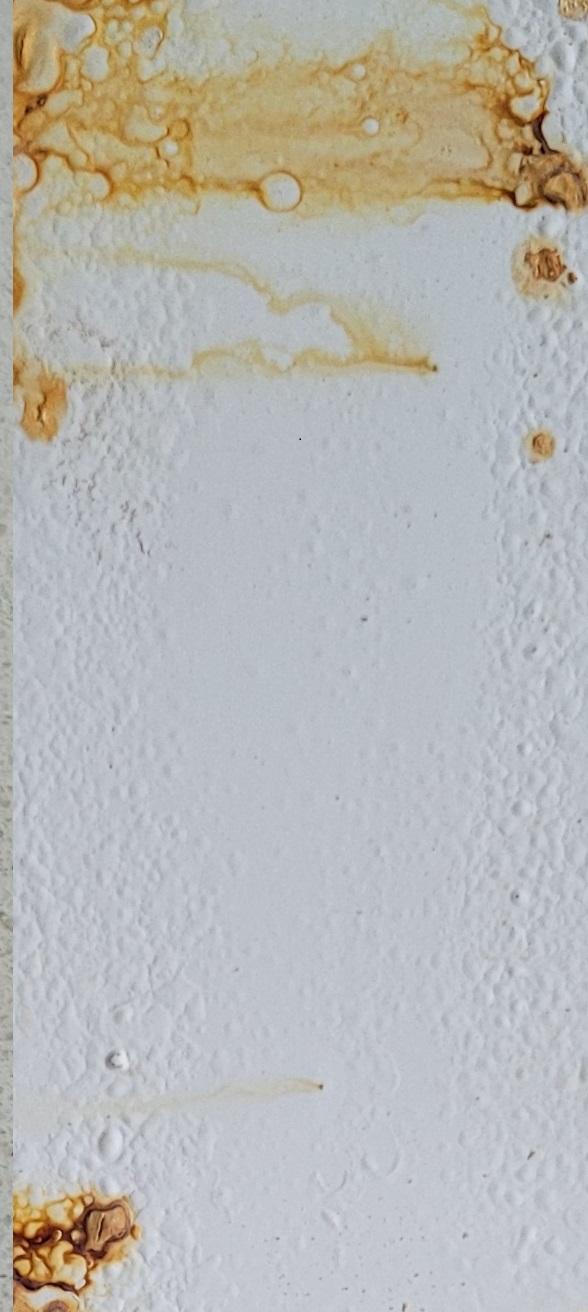

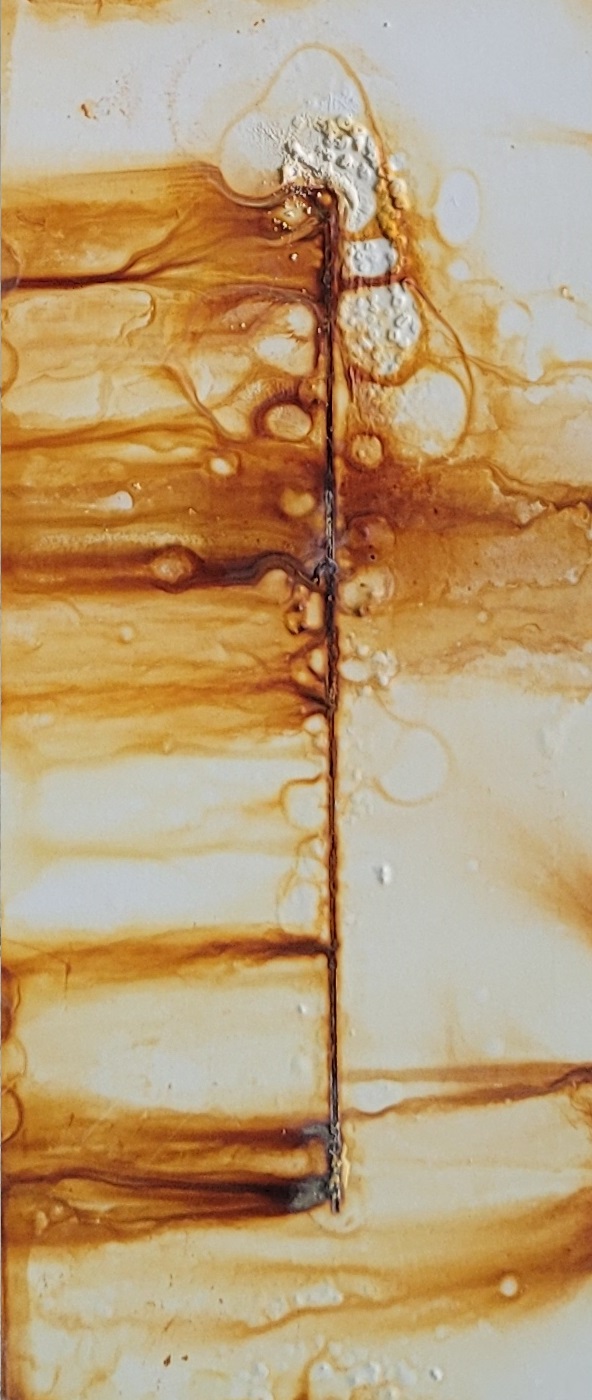

Corrosion test results for solvent-borne alkyd formulation.

Samples without incision.

The following images show samples without incision after exposure in a salt spray chamber. The test was conducted according to the PN-EN ISO 9227 (U) standard for Paints and Varnishes in an independent testing unit. The coating base used was CHS-ALKYD S 401 X 55 resin, with a volumetric content of anticorrosive pigments relative to the volume of other pigments and fillers set at 20% for all samples. The control sample did not contain any anticorrosive pigments. The exposure time for one of the samples varied due to corrosion progress and blister formation.

Evaluation of coating damage without incision over the duration of testing in the salt spray chamber.

Click below.

The evaluation was conducted by an independent research unit in accordance with the PN-EN ISO 4628 Paints and Varnishes standard. It involved determining the quantity and size of damages as well as the intensity of changes in appearance.

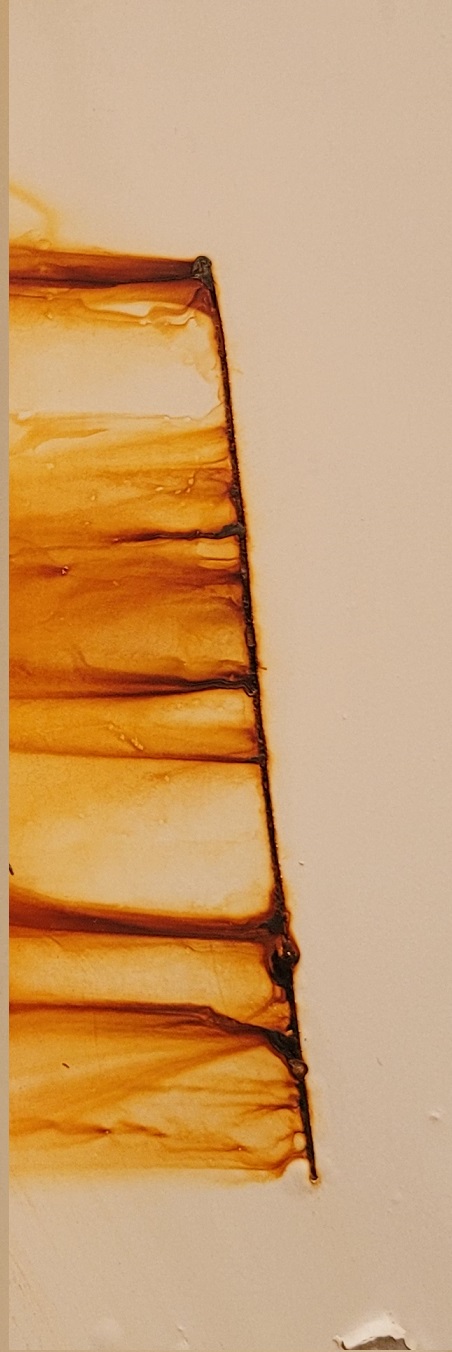

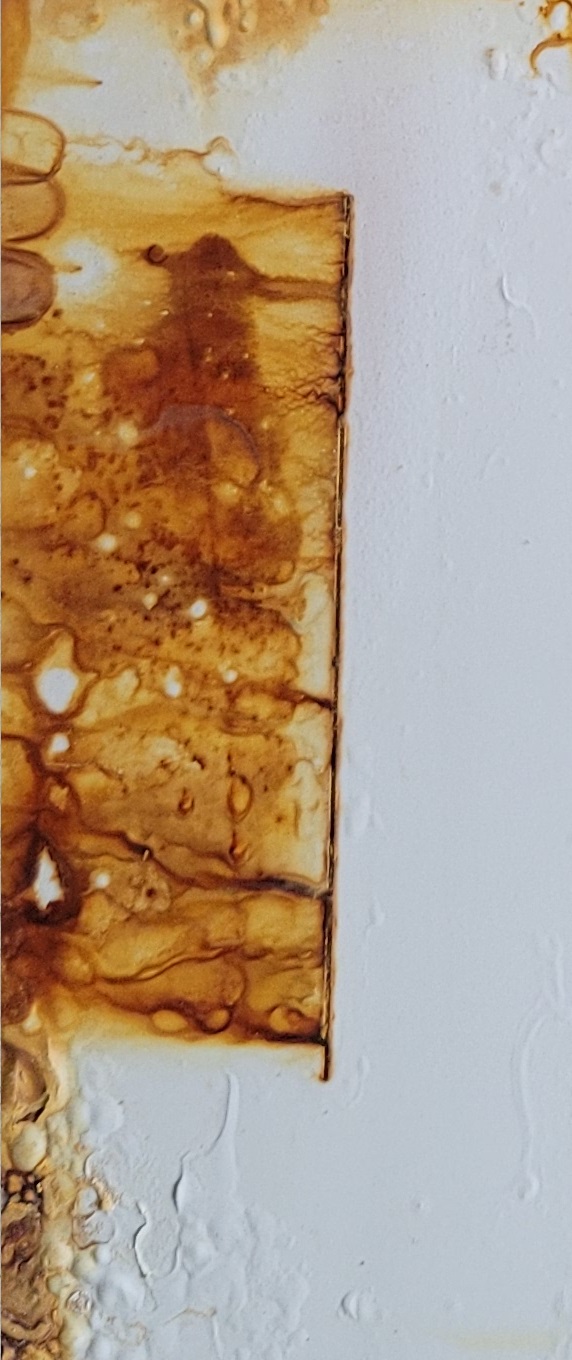

Corrosion test results for solvent-borne alkyd formulation.

Samples with incision.

The following images show samples with incision after exposure in a salt spray chamber. The test was conducted according to the PN-EN ISO 9227 (U) standard for Paints and Varnishes in an independent testing unit. The coating base used was CHS-ALKYD S 401 X 55 resin, with a volumetric content of anticorrosive pigments relative to the volume of other pigments and fillers set at 20% for all samples. The control sample did not contain any anticorrosive pigments. The exposure time for one of the samples varied due to corrosion progress and blister formation.

Evaluation of coating damage with incision over the duration of testing in the salt spray chamber.

Click below.

The evaluation was conducted by an independent research unit in accordance with the PN-EN ISO 4628 Paints and Varnishes standard. It involved determining the quantity and size of damages as well as the intensity of changes in appearance.

Where PHOSCOR® pigments can be applied?

Depending on purpose of use, PHOSCOR®

can be used with coatings bases as below

Solvent coating systems

Water coating systems

PHOSCOR® also performs very well in reactive anticorrosive paints used as primers in anti-corrosion coatings.

We appreciate your interest in PHOSCOR®

products!

Please fill below form to recieve brochure.

Contact us!

Please contact us for a futher infortmation by filling the contact form below.

© 2024 Ecor • All Rights Reserved